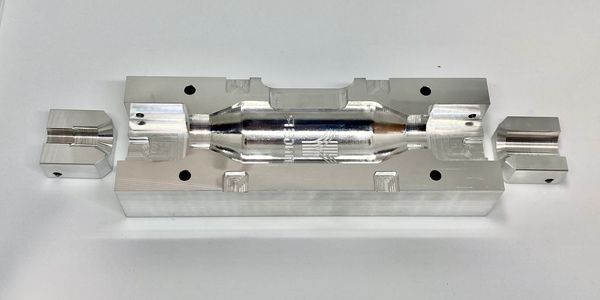

Underwater Cable Splice Kits

Splicing Made Easy

Underwater cable splice mold kits are available in both Metric and Imperial. Each kit comes with 4-6 different size cable adapters to allow on kit to cover many jobs.

.jpg/:/cr=t:45.85%25,l:0%25,w:100%25,h:46.73%25/rs=w:600,h:300,cg:true)

One Tool for Many Jobs

By design the mold is completely reusable. The innovative cable adapter design allows the user to switch between sizes quickly and easily. Sizes can even be mixed.

Complete Kits

Splice your cabling for underwater use in the field and low volume production! Includes splice mold halves, hardware for clamping, epoxy set and directions.

Options

- We can provide all molds in aluminum.

- Your company logo embossed in the mold.

- If you are regularly using a cable with a unique diameter, we can provide adapters that match your cable diameter exactly.

Custom Molds

We also offer custom molds for connectors like IE 55s, MCOMs, etc. Please let us know what you need, and we will get you a reasonable quote.

Details

Basic Splice Kit Pricing (2 Cable)

Small Metric: 7mm, 8mm, 9mm, 10mm, 12mm, 13mm - $775.00

Large Metric: 15mm, 16mm, 18mm, 19mm, 20mm - $875.00

Y-Splice Kit Pricing (3 Cable)

Small Metric: 7mm, 8mm, 9mm, 10mm, 12mm, 13mm - $1000.00

Large Metric: 15mm, 16mm, 18mm, 19mm, 20mm - $1100.00

By design the mold is completely reusable. The innovative cable adapter design allows the user to switch between sizes quickly and easily. Sizes can even be mixed.

YOUR COMPANY NAME (TEXT ONLY) CAN BE PLACED IN THE MOLD FOR A ONE TIME FEE OF $150.00.

YOUR COMPANY LOGO (GRAPHICS FILE) CAN BE PLACED IN THE MOLD FOR A ONE TIME FEE OF $225.00.

Aluminum versions are also available at +$250.00 per mold.

If a custom diameter cable adapter is required, we can replace one of the existing adapters with the custom diameter adpater for $100.00.

Note: Cable sizes very plus/minus .05, vinyl tape is included to help ensure no potting compound leakage.

WITH OUR SPLICE MOLD KITS, YOU CAN SAFELY AND CONFIDENTLY SPLICE YOUR ELECTRICAL CONNECTIONS IN THE FIELD OR IN THE LAB. DESIGNED TO CAST AND COME APART WITH EASE, THIS KIT COMES WITH ALIGNMENT PINS, TWO MOLD HALVES, ASSOCIATED MOLD CLAMPING FASTENERS, AND EPOXY.

PLEASE APPLY MOLD RELEASE TO THE INTERIOR OF THE MOLD HALVES PRIOR TO POURING / INJECTING EPOXY. TEMPERATURE CONTROLLED ENVIRONMENTS ARE RECOMMENDED. BE SURE NOT TO GET ANY MOLD RELEASE ON THE CABLE JACKET AS THIS WILL NOT ALLOW THE EPOXY TO BOND WITH THE CABLE JACKET.

Proper Use Details

1. Potting compounds

A) The kit is shipped with Scotchcast 2131. This Potting compound if best suited for field service because it sets up quickly allowing for faster demolding time. However it has certain disadvantages for customers that want to use this for more of a production mold. It has a very short working time and it is very thick or viscus. This can cause air bubbles to be trapped and not allow the compound to get into the logo features.

B) For production, a potting compound 20-2180 by a company called EPOXIES ETC. is recommended (https://www.epoxies.com/news/epoxies-etcs-casting-resin-great-for-cable-and-harness-assemblies/) This compound has a 20 minute working time and is much less viscus allowing it to release air bubbles better and get into smaller features. It will need a longer time before de-molding. I have a great deal of success using this compound.

1. Small Y-Splice kit de-mold time: 12 to 24 hours at 77F.

2. Small Single Splice kit de-mold time: 8 to 16 hours at 77F.

3. Large Y-Splice kit de-mold time: 18 to 24 hours at 77F.

4. Large Single Splice kit de-mold time: 16 to 24 hours at 77F.

2. Mold Prep

A) We highly recommend using a NON SILICONE BASED mold release. We use 2 types.

1. Partall Mold Release Hi-Temp Paste Wax 12oz Can (https://www.rexco-usa.com/product/partall-hi-temp-wax/)

2. Mann Release Technologies Ease Release 200 14 Fl. Oz. (https://www.staples.com/Mann-Release-Technologies-Ease-Release-200-14-Fl-Oz-70023/product_2135404?ci_src=17588969&ci_sku=2135404&KPID=2135404&cid=PS:CRL:GS:SBD:PLA:OS&gclid=Cj0KCQiApY6BBhCsARIsAOI_GjYVtZDR5IQJPqBQtNrU7un5DZz-IxY8dl2dOwZRLOiLFeSUsm-olpcaAloJEALw_wcB)

B) When using the paste mold release you will need to run a wood or plastic tooth pick in the logo text/design to remove excess wax.

C) Lastly ensue the mold is at room temperature or slightly higher. This will allow air bubbles to flow better and help with even cure.

3. Cable Prep

A) To ensure good mechanical adhesion of the potting compound the surface of the cable should be roughed up with 80 to 60 grit sandpaper and thoroughly cleaned with Isopropyl alcohol.